LIGHTNING PROTECTION

This termination spark gap just had a tough time. However, it did save the resistor from that stress

Some time ago, I thought that connecting to ground or simply disconnecting my coax lines was enough to prevent static charges from attacking my sensitive equipments. Armed with an heavy gauge wire connected to ground via a single 10 foot galvanized steel rod and a couple of coax ground blocks connected to a 5 foot 5/8 inch copper plated rod at the basement entrance, I had the feeling that grounding would improve low frequency reception and with less concern, protect against static discharge. In July of 2007, what I thought that could only happen to others happened to me. Lightning struck nearby evaporating over 100 feet of a Beverage electric fence wire. This was more than just static! My newly installed remote switcher also went into smoke. Then the surge followed the coaxes and control lines up to my shack inside the house blowing up power supplies and one splitter. Fortunately, I've also added switches at both phaser antenna inputs which ground them when I'm not DXing. If it would not have been for all that "primitive" grounding, it may have blown my receiver and who knows, put fire in the room! All those little things may have slowed down the surge strength.

This is how the remote antenna switcher looked like recently installed with cover off

This is how it looked shortly after the strike. Along with the Beverages, there was two 100 foot long wire connected . One of them made of electric fence wire, was cut and the box plastic cover was also blown away

After that event, my family and a few neighbours were feeling a bit insecure in thinking that my installations may attract lightning becoming a pest for the whole neighbourhood. I had to do something in order to secure everybody including myself. From there, I began looking for lightning protection and grounding over the Internet. I did learn something which was put in practice in the following weeks. I don't pretend myself being an expert but if this modest knowledge can serve you, I will be pleased.

Among all I've found which appeared to be serious, a basic rule prevail: A single point ground and ground bonding. That single point ground is called in practice a bulkhead entrance. This is some kind of a unique point, a metal plate made of copper ideally, where all coax and control lines should be connected to ground before entering home. This single ground point MUST be shared by ALL lines that enter your house. This is rather utopian especially when your house is already built but if you are about building one, you have more chance to build an optimal grounding system. Be ready though to put extra money. So we speak of telephone, cable, satellite cable and main power entrance neutral which should all converge to that same ground point in order to keep the overall ground impedance as low as possible. Here's how W8JI, Tom Rauch, explain with better words this concept. He also explain what is the enemy and how we should take care of it. This is what I intended to do by installing next to the basement window, a common point ground using wide copper foil mounted on a wooden frame and connected to a 5/8 inch -

Of the three splitters, one just couldn't stand it (left). Those are located at my shack next to my chair. Back then, I used separate windings between primary and secondary. Now they all connect to a common ground plate

I then ordered from Basic Copper a 25 pound (which gives 108 feet), 6 inches wide, 10 mil copper foil roll that I've used to bond every single radio equipments, including the utility entrance panel and the cold water line coming out from earth. Sections of the foil has been cut to make it narrow. I also used a second 5/8 inch -

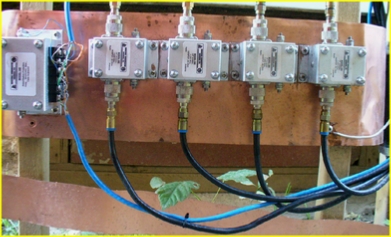

My bulkhead unique ground entrance with the four coax lines and controls line all connected through ICE DC blocking lightning arresters. The ground plate is a section of six inches wide copper foil. On the left side, it connects with the copper plated ground rod (not shown) after coming out from indoor trough one side of the window. On the right side, it re-

This is how the matching transformer housing was left. See how hardly the ground terminal have been in demand!

For good measure, I've added to the Beverage matching unit a 90v surge arrestor between the hot terminal and ground, adding extra protection and another spark gap between those same two posts. The DX Engineering matching units should have internal spark gap as stated in their specs but frankly, when servicing the defective unit, except for PC board spacing, I didn't find any reasonable spark gap.

In grounding system literature, the use of copper foil is recommended for its low impedance compare to a round conductor, even heavy gauged. The impedance should be as low as possible because surge energy from lightning produces a wide range of RF harmonics. You need to insure that you provide an attractive route to ground for that energy otherwise; it will find ground through your appliances and equipments. Ideally, you must use more than one ground rod with good spacing between them in order to dissipate all that energy through earth. The cold water entrance near ground is my first ground rod, I have a second rod 5m further and the third one around 10m from the second one. As stated before, with a house already built, you need to adapt your installation.

The copper foil ends bonding to the main utility panel with metal screws

This is where the foil goes outside from inside the basement of our centenary old house acting as a unique ground point along with the ground rods then, entering back to end narrower up to the upper storey shack ground plate

Not too classy but well bonded to the cold water entrance near utility panel. After preparing the two metallic surfaces, I've added conductive compound all tightened with stainless steel screws

Upper storey ground plate with switching board and preamp on the left. Receivers and phaser not shown on the upper right over the desk also each bonded to the plate

When installing the foil conductor, it is recommended to leave it as straight as possible without sharp bends. It may sound easy but this is tough to do. The best way I've found to bond a 6 inch copper to a ground rod is to rap it around producing some bending anyway. I know that there are clamps on the market for this purpose but only up to around two inches wide. We'll see in the future if my setup withstands bad conditions. Following all the "right" rules from various studies, I would had to change many things around the house, move utility entrance as adding many more rods but it's almost impossible to do. The best I could do is put as more rods as I can, use a large foil to bond everything from the basement electrical panel up to my upper storey receiving station. All you can do is try to be near perfect.

A couple of power supplies also bonded to the ground plate behind the desk. The copper strap entering from the floor is connected to the main bulkhead entrance outside near the basement

For more info about grounding and lightning protection, you can have a look at the Polyphaser website and at Morgan Systems technical tips page. Remember that based on these researches, I learned a little something about grounding. You should consider at least, giving some interest at this topic. If I did it, you certainly can do it…

A few more photos of my small disaster...

MAY 2021 SHACK RELOCATION

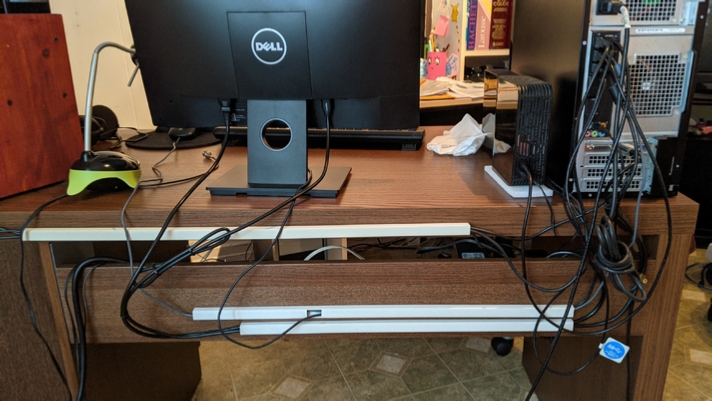

At last, more space as I moved the shack from a second storey narrow corner to a more spacious area at ground floor. There you see what’s left from the re-

Above, performing some cable and ground connections management. The ground sheet and the other components are carefully located in order to fit my new desk

Preliminary testing

Behind the shack desk cable management

Cables and ground sheeting coming from the outside through the basement, then entering right into the shack, which is located directly above

Page updated on Dec 2023

| Receiving Station Setup |

| Receivers |

| Antennas |

| Line / Antenna switchers |

| Lightning protection |

| Others |

| Conventional receivers |

| Microtelecom Perseus |

| SDRPlay |

| Beverages |

| K9AY |

| PA0RDT Mini-Whip |

| Miscellaneous |

| Asian audio files |

| African audio files |

| European audio files |

| Middle-East audio files |

| Latin American-Caribbean audio files |

| 2015 St-Patrick' solar storm audio files |

| DX Curiosities |

| August 2007 bandscan |

| August 2014 bandscan |

| FMDX equipments |

| FM logs 2017-2018 |

| FM logs 2020 |

| FM logs 2021 |

| FM logs 2022 |

| FM logs 2023 |

| FM logs 2025 |